automatic capsule filling machine working principle

The capsule before sent for packing needs to be properly processed and filled with the help of a capsule Filling machine. NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole.

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Full automatic capsule filling machine is a newly created.

. Pharmaceutical processing involves a number of operations and capsule filling is one such important part of the process. This section is the empty capsule feeding mechanismwhich is to load the empty capsules into the mold for the next procedure body and cap separation. Liquid Filling Machine Its Principles.

Working Principle of A Capsule Filling Machine. Aug 24 2021. Aipak automatic capsule filling machine working principle.

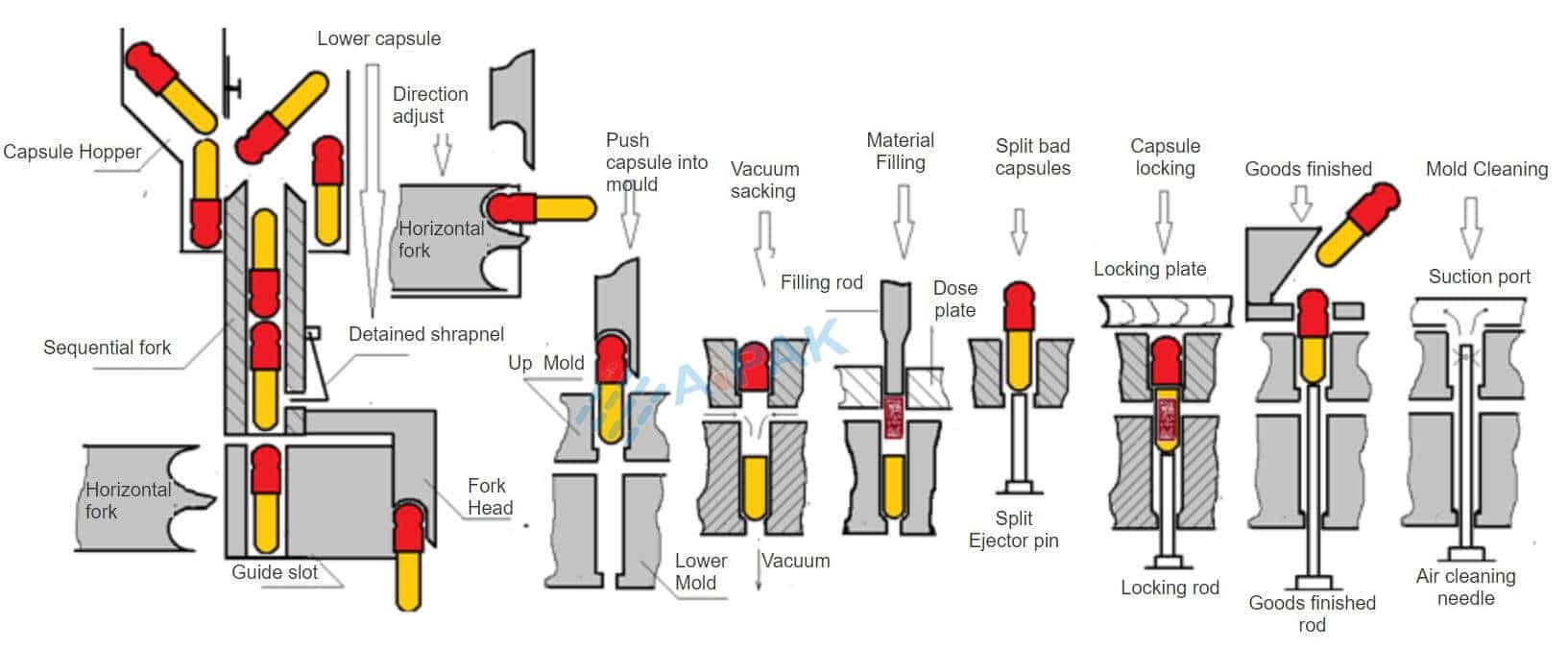

- Thursday June 6 2019. The capsules are rectified caps and bodies are separated active pharmaceutical ingredients API is filled wasted capsules are rejected capsules are locked in. The company established in 1995 and was one subsidiary company of.

Lets show how is the capsule filling machine workingIntroduction and profileWuhan Sino Joinsun. Over 5000 happy customers. This can be done either manually or by means of an automated capsule filling machine.

The capsule before sent for delivery needs to be properly processed and filled with the help of a capsule filler. Automatic capsule filling machines are extremely durable and reliable when it involves capsule filling and maintenance of the integrity of the filled capsules. Automatic Capsule Filling Machine.

Automatic capsule filling machine is a fully automatic capsule filling machine with which capsule separation filling and locking can be done automatically. Rent buy or lease Filling Capsule Equipment Machines. The capsule filling machine works in a step-by-step process that is as mentioned below.

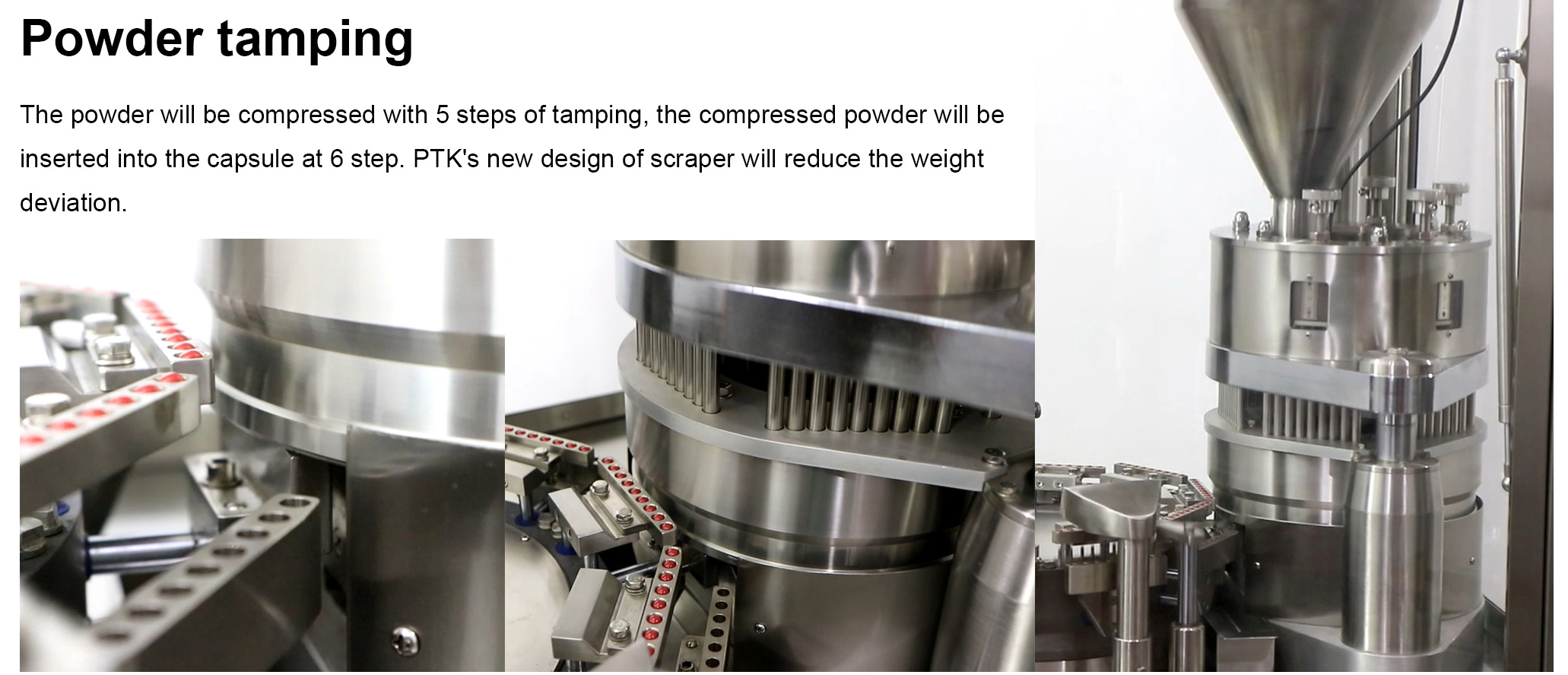

In short the working principle of a tamping type capsule filler involves a number of stages whose consistency and performance should be monitored. RICH PACKING is here to introduce you to the basic working principle of the cartoning machine. It has 9 holes turning out a highest output of 1200 capsulesminute.

If you set up or build a company or factory and need to purchase and use an automatic cartoning machine then you need to first understand the working principle of the automatic cartoning machine. Whether you complete the filling process with a new machine or with a used capsule filler the filling machine takes over the entire filling process. These machines increase production and increase the efficiency of the production process.

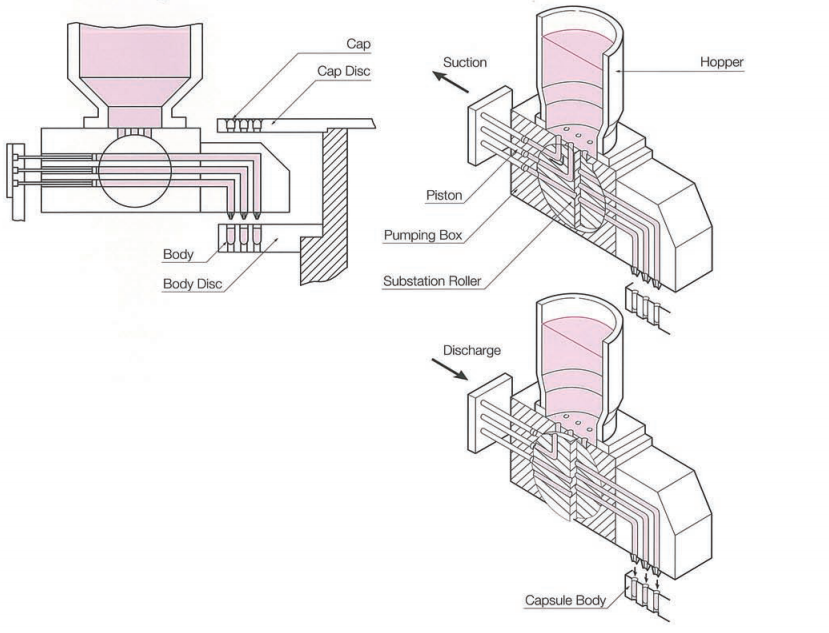

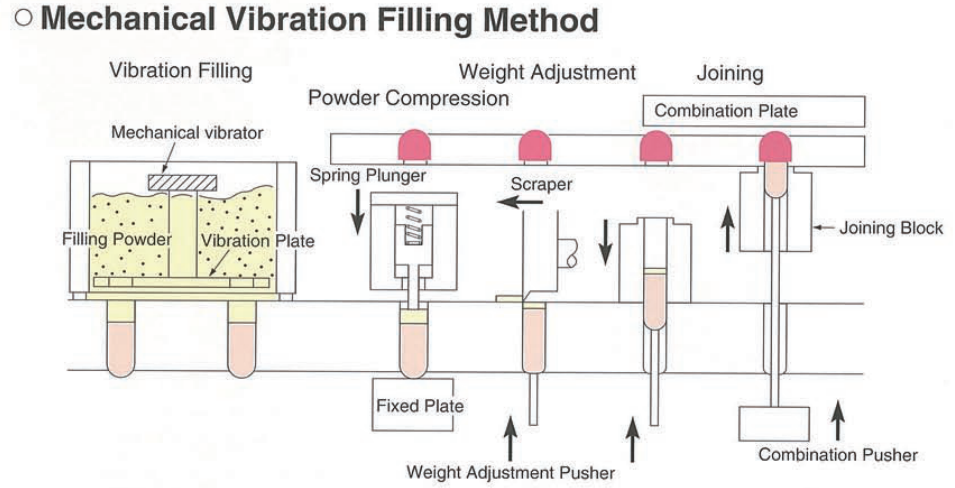

Working Principles of Various Filling Machines 1. This can be done either manually or by means of an automated capsule filling machine. A dosator machine may have two segments.

Operating principles of a capsule filling machine. When the fork is sent down six capsules are delivered at a. Separation of capsule caps from bodies.

Automatic capsule filling machine working principle. A dosator machine with two. The machine that can greatly improve production efficiency and reduce labor costs.

The capsule before sent for delivery needs to be properly processed and filled with the help of a capsule filler. In stock ready to ship. The capsules are rectified caps and bodies are separated active pharmaceutical ingredients API is filled wasted capsules are rejected capsules are.

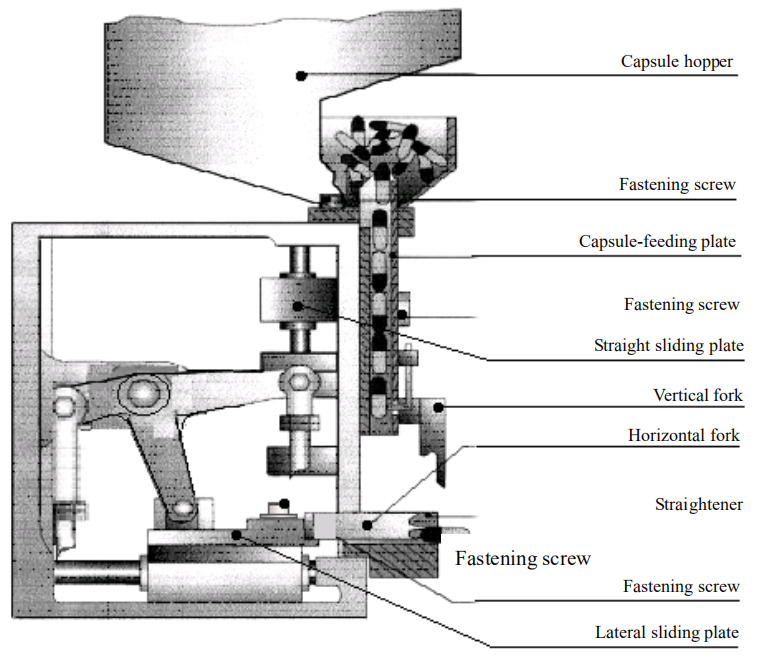

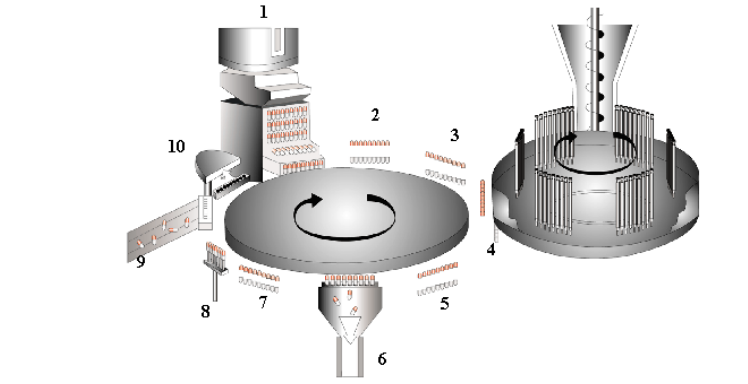

This can be done either manually or by means of an automated capsule filling machine. Automatic encapsulator also can work as an entire system of fully automatic capsule filling line by attaching additional equipment as online capsule polishing machine dust extractor. During the operation the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding plate one by one.

Dosing of fill materialformulation filling the bodies. The Working Principle of SaintyCo Dosator Capsule Filling Machine. Even though the process seems simple and straightforward any failuremalfunction in any of the tamping pins may cause serious loss high rate of capsule rejection.

Pharmaland Technologies is a Toront o-based Canadian company offering qua lity cost-effective and innovative pharmaceutical machinery on a global scale. The main working principle of the automatic capsule filling machine is that when the machine is running the capsules in the capsule hopper will vertically enter the delivery fork one by one. Ad Browse through 75 Used New Filler Powder Capsule Machines.

Division of capsule caps from their bodies. Ejection of filled capsules. In this station the upper and lower parts of the capsule body are separated by vacuum suction.

Working Principle of Capsule Filling Machine. The working principle of soft gelatin capsule filling machine involves preparing gelatin fill material preparation and actual encapsulation process. The system is such that the powder bed is on one side while the empty capsule body is on the opposite side.

Reserved work position 10. The liquid filling machine works when the pressure is high. The most common type of carton packaging machine is.

If you run a large manufacturing operation the use of automated capsule fillers is mandatory. Hereyou will see most of your empty capsules are connected capsules as whose body and cap are joined together originally. You can then process the Softgel capsules further by drying polishing or printing.

Capsule filling machines should all have the following operating principles in common. Home About. 1 Empty capsules are discharged from the capsule hopper and pushed into position 1 sequencing station orderly by the push rod through the capsule tank.

Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process. The positioning of colourless translucent capsules in the capsule filling tray. This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight when the amount of pressure of the liquid reservoir is equal to the amount of air present in the.

Every machine has its own working method. Now with the continuous improvement of the filling technology the automatic capsule filling machine is becoming higher and higher automated and the filling speed is getting faster and faster from tens of thousands to hundreds of thousands or even hundreds of thousands of filling per hour Therefore the equipment confirmation and commissioning must be done before. Rejoining of caps and bodies.

Rectification orientation of the bad gelatin capsules.

Njp800 Industry Big Automatic Capsule Filling Machine China Capsule Filling Machine Manual Capsule Filling Machine Made In China Com

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

Automatic Capsule Filling Machine Working Principle Ipharmachine

Filling Machines Their Working Principles

Automatic Capsule Filling Machine Pharmaceutical Machinery Equipment Shanghai Metal

China Capsule Filling Machine Company Manufacturer Supplier Tyjx

Capsule Filling Machine The Blueprint Guide Saintyco

Automatic Capsule Filling Machine The Most Ultimate Importing Guide Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

Preparation Equipment Working Principle Animation Hunan Grand Packaging Co Ltd

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine High Speed Capsule Filler

China The Newest Fully Pharma Automatic Capsule Filling Machine China Capsule Filling Machine Capsule Filler

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

How Different Types Of Capsule Filling Machine Work By Lodhapharma Issuu

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd

Capsule Filling Machine Fully Automatic Capsule Filling Process Working Animation Project Youtube

Automatic Capsule Filling Machine The Machine Introduction Manual Hunan Grand Packaging Co Ltd